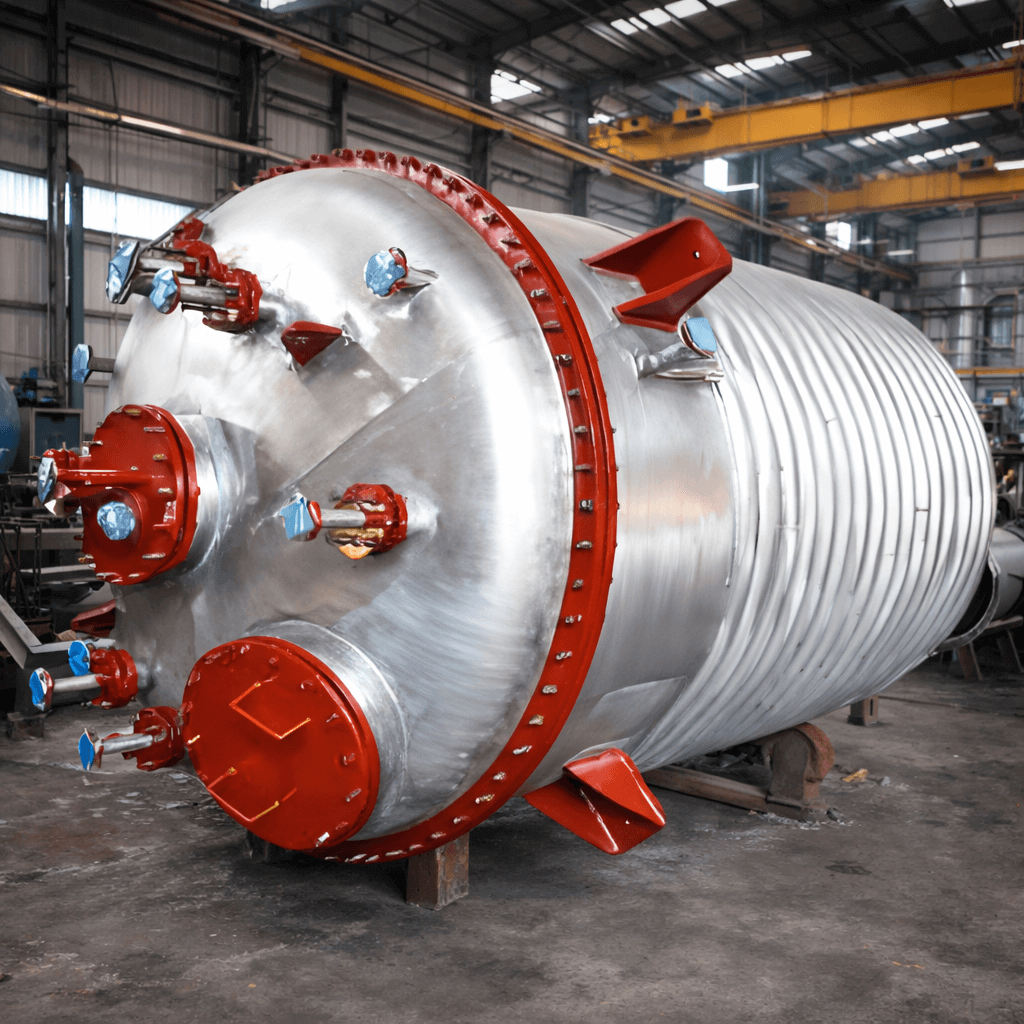

SS/MS Crystallizer

An SS/MS Crystallizer is an advanced processing system used to convert liquid solutions into high-purity solid crystals through controlled cooling, evaporation, or precipitation. It ensures accurate crystal formation for pharmaceuticals, chemicals, dyes, pigments, and specialty manufacturing industries.

Fabricated using high-grade Stainless Steel (SS304/SS316) or Mild Steel, these crystallizers offer uniform temperature control, efficient mixing, and optimized crystal growth. With advanced agitation, heating/cooling jackets, and vacuum capability, they deliver consistent product quality and maximum yield.